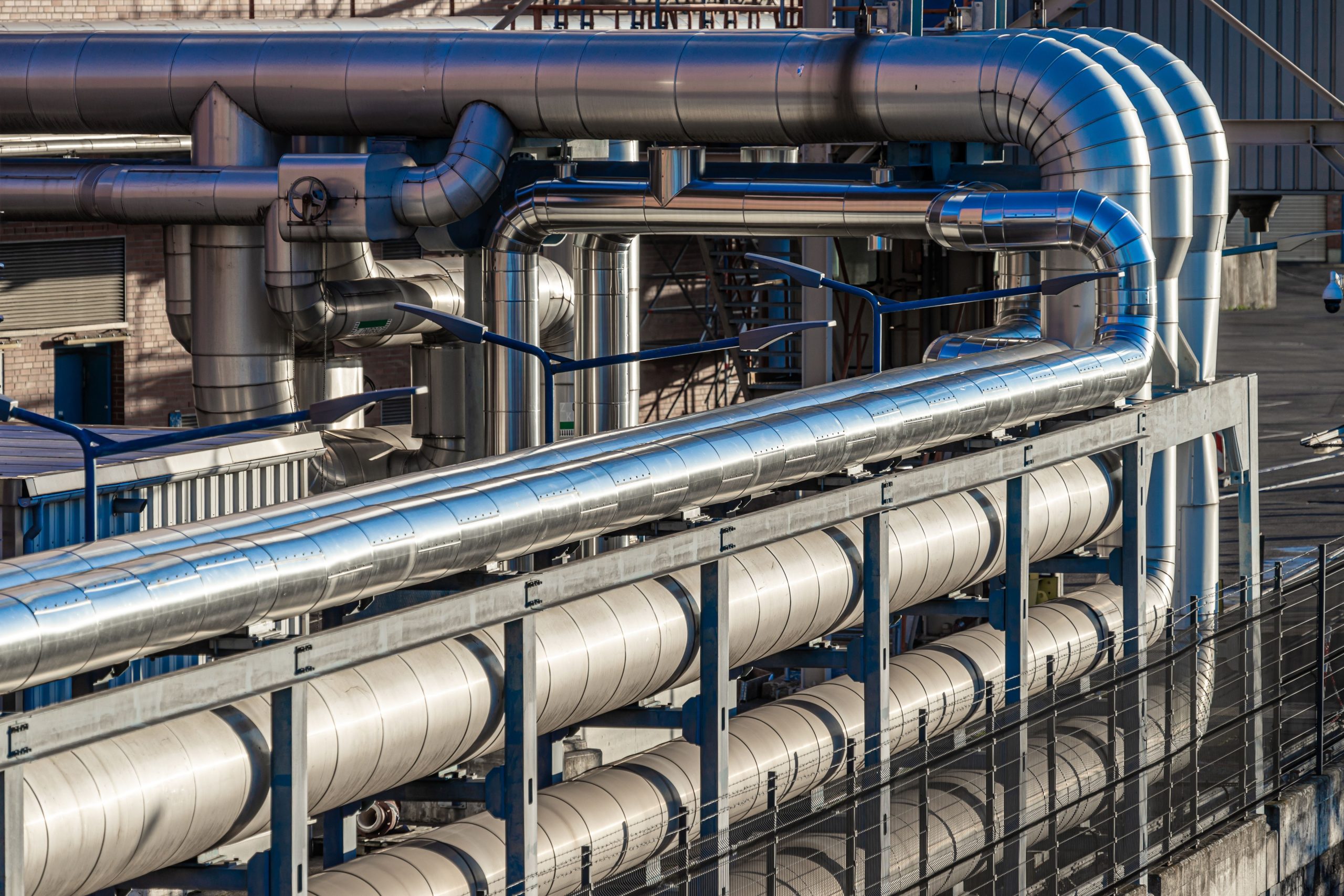

Mod Industrial Services specializes in pipeline installation to ensure safe, efficient, and long-lasting operation of industrial facilities. From refineries, petrochemical plants, and power stations to cement and offshore facilities, we deliver solutions across a broad scope—from process lines to utility piping. We manage the entire process end-to-end, from project kickoff to commissioning, delivering services in full compliance with industry quality, occupational health, and safety standards.

Our Pipeline Installation Services

Industrial Piping Installation

We install piping systems designed to withstand high pressure, temperature, and chemically aggressive environments. By offering engineering solutions tailored to each facility, we ensure process continuity.

Piping with Various Material Types

We execute the installation of corrosion-resistant stainless steel, carbon steel, alloy steel, galvanized, copper, PVC/CPVC, HDPE, GRP/FRP, and high-strength carbon steel piping.

Heat-Traced Piping (Steam Tracing)

Mod Industrial Services provides advanced steam tracing installation services to control temperature and optimize processes in industrial facilities. Our experienced team delivers project-compliant installation of steam tracing systems, including contemporary stainless-steel steam tracing solutions applied worldwide.

High-Pressure and High-Temperature Lines

We professionally install piping systems designed for the high-pressure, high-temperature, and corrosive conditions encountered in power plants, heavy industrial facilities, and offshore platforms. In offshore applications in particular, we perform welding and installation of heavy-wall, heavy-duty piping with high precision in accordance with ASME, ANSI, and API standards, following our certified welding procedures (WPS, PQR, WPQ).

Testing, Cleaning, and Commissioning

Upon completion of piping installation, the system is verified for pressure integrity through project-specific test procedures, primarily hydrostatic testing. This is followed by internal cleaning/flushing, after which the system is commissioned and made ready for operation. All testing and commissioning activities are carried out in line with applicable international standards. Our objective is to ensure the line operates safely, efficiently, and without issues.

Industries We Serve

Mod Industrial Services provides mechanical installation solutions in the following industrial facilities: Energy: Thermal power plants, hydroelectric power plants

Petrochemical and Refinery: Oil refineries, petrochemical facilities

Offshore: Offshore platforms, drilling vessels, FPU units

Cement and Mining: Cement factories, mining sites, and processing plants

Shipyards and Marine Construction: Ship repair, maintenance, and new build projects

Iron and Steel: Blast furnaces, converters, rolling mills

Industrial Plants: Food, oil, chemical, paint, and pharmaceutical manufacturing facilities

Frequently Asked Questions (FAQ)

What is an industrial piping system?

An industrial piping system enables the safe and controlled transport of liquids, gases, steam, or chemical media within a facility. Common in refineries, petrochemicals, energy, cement, and offshore sectors, these systems are critical for process continuity and overall plant efficiency. Material selection, installation quality, and testing procedures directly affect system performance and service life.

What is industrial piping installation?

Industrial piping installation is the project-compliant erection of pipelines carrying liquids, gases, or steam. These lines are critical to process continuity, safety, and production efficiency.

Which materials are used in piping?

At Mod Industrial Services, we install piping in accordance with project documentation using materials such as stainless steel, carbon steel, alloy steel, and specially coated pipes. Materials are defined in the project based on employer specifications and criteria including corrosion resistance, operating temperature, and pressure.